- English

- 简体中文

- tiếng Việt

- Indonesia

- שפה עברית

- Hrvatski

- Malti

- lugha ya Kiswahili

- Hausa

- Монгол хэл

- O'zbek

- Հայերեն

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Norsk

- český

- ελληνικά

- український

- Javanese

- فارسی

- Burmese

- български

- ລາວ

- Azərbaycan

- Slovenský jazyk

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- தமிழ்

Air Compressor Noise Suddenly Increasing? 7 Causes & Solutions for Screw Air Compressors

2025-08-07

I. Abnormal Noise in Air Compressors: Mechanical Component Issues

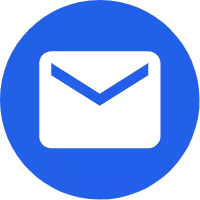

1. Bearing Wear in Screw Air Compressors

- Screw air compressors, with their high-speed operation, are prone to bearing wear over time— a common issue in air compressors.

- Typical sign: A gradually intensifying metal friction sound.

- Solution: Promptly replace with original manufacturer bearings designed for screw air compressors.

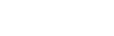

2. Rotor Imbalance in Screw Air Compressors

- For screw air compressors, rotor carbon buildup or deformation can disrupt dynamic balance— a critical issue unique to these air compressors.

- Typical sign: Noticeable vibration alongside increased noise.

- Solution: Professional dynamic balance correction for the screw air compressor’s rotor system.

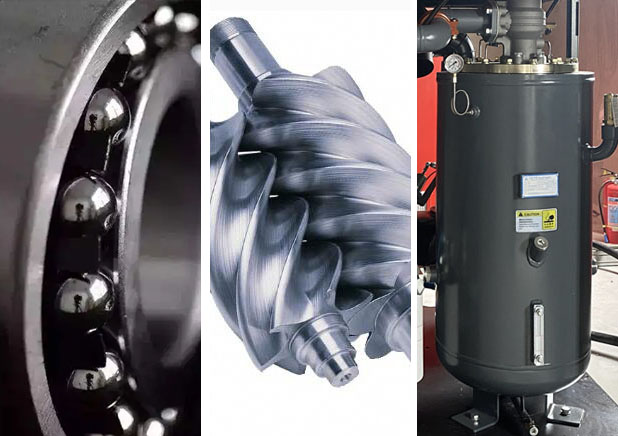

3. Lubrication System Failures in Air Compressors

- Insufficient or degraded lubricating oil impairs lubrication in both air compressors and screw air compressors.

- Suggestion: Regularly check oil levels; replace lubricants on schedule, using only the specified special oil for screw air compressors.

II. Noise from Installation & Usage Issues in Air Compressors

1. Improper Installation of Screw Air Compressors

- Unlevel foundations or loose anchor bolts are common causes of increased noise in air compressors, especially for screw air compressors.

- Key check: Tightness of all fixing bolts.

- Solution: Re-level the base and securely fasten bolts to stabilize the screw air compressor.

2. Intake System Problems in Air Compressors

- Clogged air filters increase intake resistance— a frequent issue in both air compressors and screw air compressors.

- Maintenance tip: Replace filters every 2000 hours (a standard practice for most air compressors).

- Note: Intake valve malfunctions in screw air compressors require professional inspection.

III. Maintenance Guidelines for Air Compressors (Especially Screw Air Compressors)

1. Regular Maintenance Plan for Screw Air Compressors

- Check bearing condition quarterly (vital for air compressor longevity).

- Test rotor balance every 6 months (critical for the performance of screw air compressors).

- Establish a detailed maintenance log for your air compressor.

2. Abnormal Noise Response for Air Compressors

- If unusual noise occurs in your screw air compressor, shut it down immediately.

- Document noise characteristics (e.g., pitch, timing) to aid repairs.

- Contact certified technicians experienced with air compressors, particularly screw models.

By following proper usage and regular maintenance, you can effectively prevent noise issues in air compressors— especially screw air compressors. This extends equipment life and ensures stable operation. Always choose genuine parts for your air compressor to maintain optimal performance.